In the steel industry, the demand for enhancing production efficiency and ensuring handling safety has been on a continuous rise. As a result, an increasing number of overseas hot-rolling mills are opting to replace their traditional clamps with the innovative translational steel plate stabilizing clamps. This article delves deep into the core technical advantages of the specially designed translational clamps for hot-rolling mills independently developed by Tiding Heavy Industry.

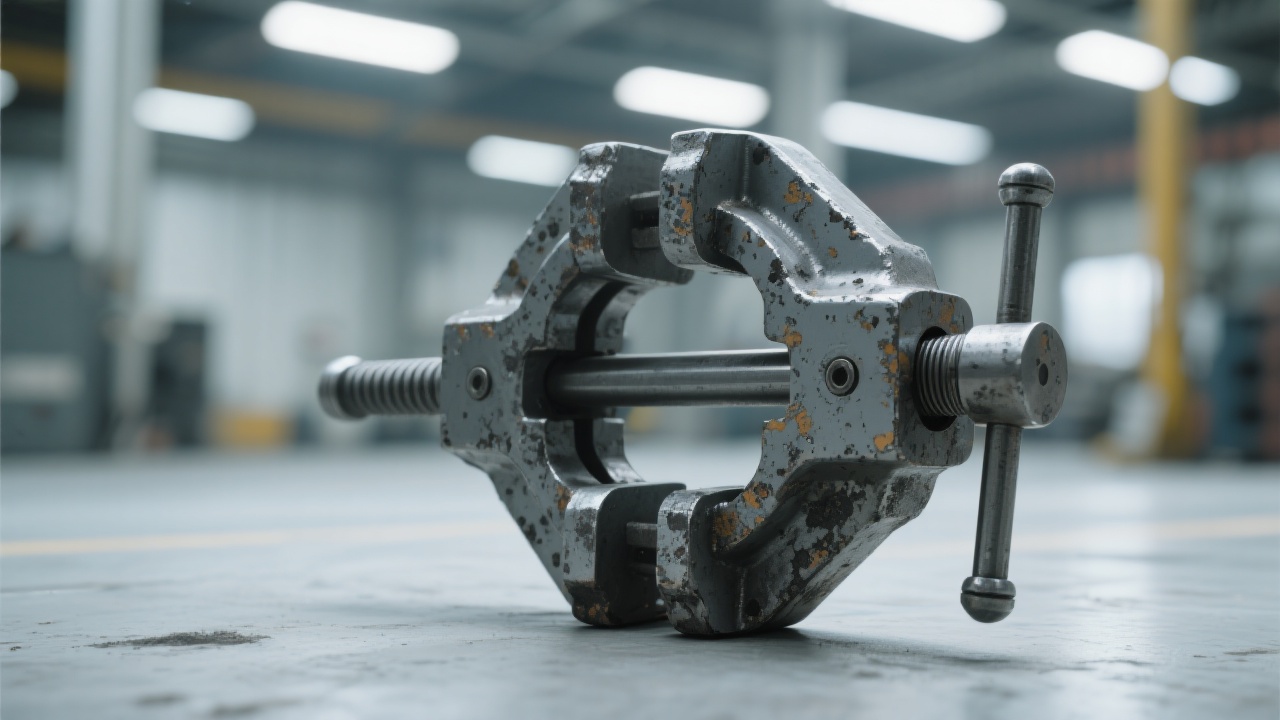

Traditional clamps have long been plagued by issues in stability and adjustment efficiency. In hot-rolling mills, the instability of traditional clamps can lead to a staggering 20% increase in the risk of accidents during steel plate handling. Moreover, the slow adjustment process of these clamps can cause a productivity loss of up to 15%. The translational clamps, however, are engineered to solve these critical problems head - on.

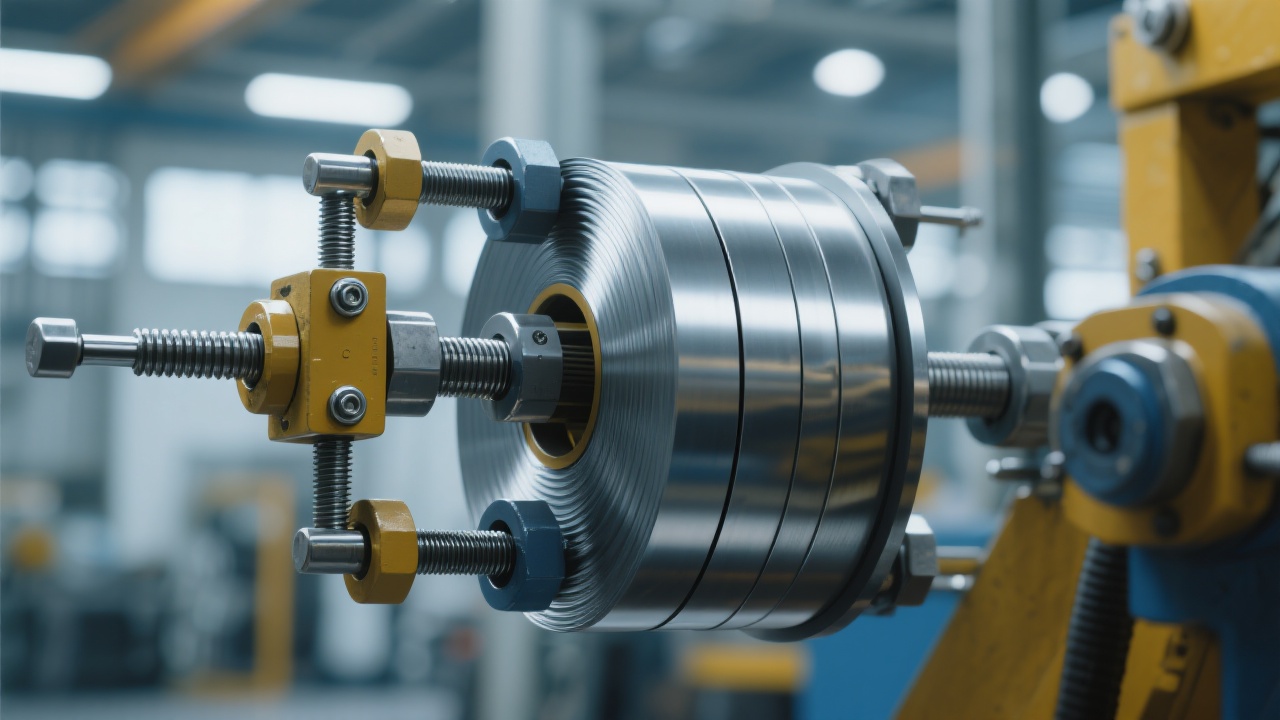

The unique transmission mechanism of the translational clamps is a game - changer. Unlike traditional clamps, it is designed with a more efficient gear - based system. This system reduces the energy consumption by approximately 18% during the clamping process, as shown in industry - wide tests. The design also minimizes wear and tear, extending the service life of the clamps by up to 30%.

Precision is key in steel plate handling. The translational clamps offer an astonishing clamping precision of ±0.5mm. This high - level precision ensures that the steel plates are firmly held in place, reducing the risk of slippage during lifting and transportation. In contrast, traditional clamps typically have a precision of ±2mm, which is far less reliable.

With a high - strength alloy structure, the translational clamps can bear loads of up to 50 tons. This is a significant improvement compared to traditional clamps, which usually have a maximum load - bearing capacity of 30 tons. The enhanced load - bearing capacity allows for the handling of larger and heavier steel plates, increasing the overall efficiency of the production process.

The rapid adjustment mechanism of the translational clamps enables quick adaptation to different steel plate sizes. It can complete the adjustment within 30 seconds, while traditional clamps may take up to 2 minutes. This time - saving feature can lead to a remarkable 25% increase in the daily handling volume.

The translational clamps are highly adaptable to various working conditions. Let's take a look at some specific cases:

In the continuous casting process, the clamps' high - precision clamping and rapid adjustment features are crucial. They ensure the smooth transfer of the newly cast steel plates, reducing the production cycle time by about 12%.

During the hot - rolling process, the high load - bearing capacity of the clamps allows for the efficient handling of hot - rolled steel plates. This has been proven to increase the production efficiency by 15% in multiple hot - rolling mills.

In port logistics, the clamps' stability and rapid adjustment capabilities are essential for the quick loading and unloading of steel plates. This can reduce the port handling time by up to 20%.

Anonymous customer feedback has consistently praised the performance of the translational clamps. One customer reported a 20% reduction in maintenance costs after switching to these clamps.

Are you still unsure whether your production line needs to upgrade to translational clamps? Do you want to know the must - check technical parameters before making a selection? Click here to get more information and let us help you make the right decision for your business's continuous and efficient growth.