In the modern steel industry, the pursuit of high - efficiency, safe, and intelligent production has become an inevitable trend. Dalian Tiding Heavy Industry Co., Ltd. has developed a revolutionary product - the power - type slab clamp, which is attracting more and more attention from steel enterprises around the world. This article will conduct an in - depth analysis of its technological innovation, application advantages, and industry value.

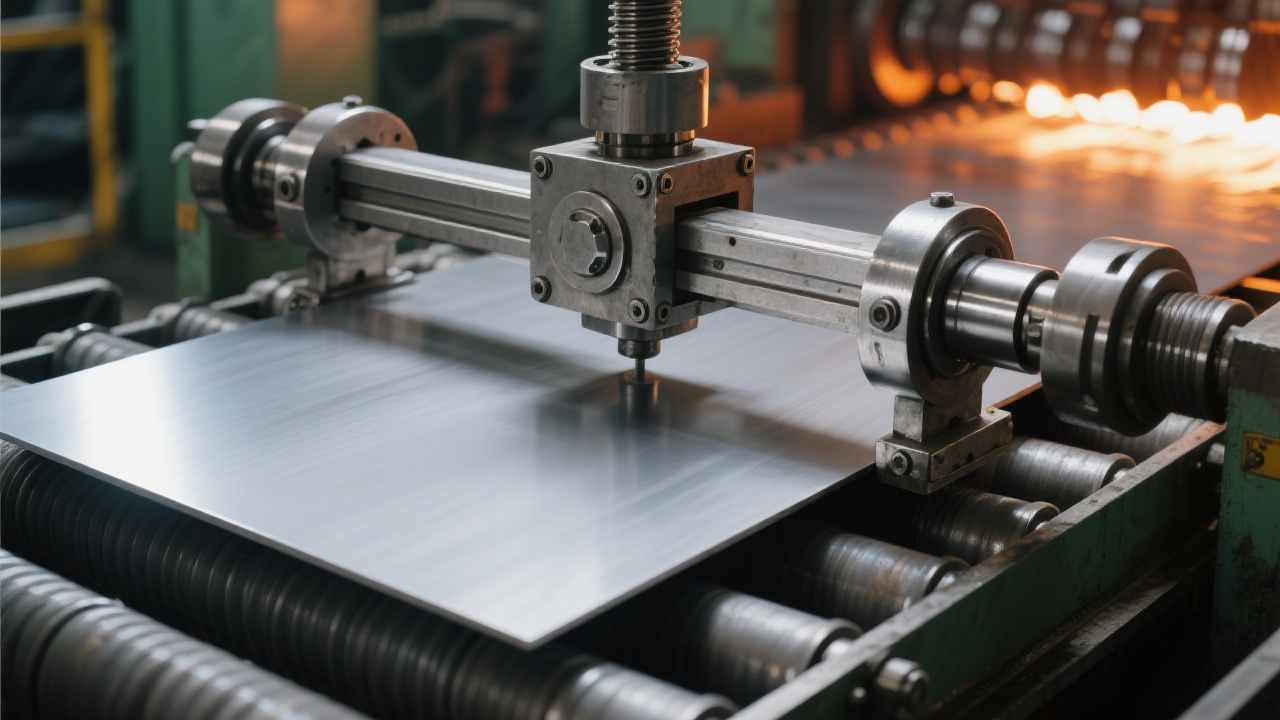

The power - type slab clamp developed by Dalian Tiding Heavy Industry Co., Ltd. features a combination of high - strength alloy steel and an advanced hydraulic automatic adjustment system. High - strength alloy steel provides the clamp with excellent mechanical properties. According to industry research, compared with traditional carbon steel clamps, the strength of clamps made of high - strength alloy steel can be increased by about 30%, and the wear resistance can be improved by about 25%. This makes the clamp more durable in high - temperature and high - load working conditions.

The hydraulic automatic adjustment system is another highlight of this product. It can automatically adjust the clamping force according to the size and weight of the slab, ensuring stable clamping in various situations. Moreover, the system has a fast opening and closing performance. Tests have shown that the opening and closing time of this power - type slab clamp is about 30% shorter than that of traditional clamps, which greatly improves the operating efficiency.

In the steel production process, high - temperature and high - load working conditions are common challenges. Traditional clamps often face problems such as reduced clamping force and structural deformation at high temperatures. The power - type slab clamp developed by Dalian Tiding Heavy Industry Co., Ltd. has excellent high - temperature resistance. It can maintain stable performance at temperatures up to 600°C, while traditional clamps may experience significant performance degradation above 400°C.

In addition, in terms of structural stability, the use of high - strength alloy steel and a reasonable structural design enable the clamp to withstand high loads without deformation. In a high - load test, the power - type slab clamp could stably lift slabs weighing up to 50 tons, while traditional clamps of the same size could only handle about 35 tons.

In the cold rolling finishing process, precision and stability are crucial. The power - type slab clamp can accurately clamp the slab, ensuring the quality of the finishing process. For example, in a large - scale steel enterprise, after using this power - type slab clamp, the defective rate of cold - rolled products decreased from 3% to 1.5%, and the production efficiency increased by about 20%.

In the logistics and transfer of steel products, the power - type slab clamp also shows significant advantages. Its fast opening and closing performance and stable clamping force can improve the transfer efficiency and reduce the risk of slab falling. In a steel logistics center, after the application of this product, the transfer efficiency increased by about 25%, and the accident rate decreased by about 40%.

Dalian Tiding Heavy Industry Co., Ltd. uses MSC NASTRAN simulation analysis and Teamcenter PDM full - process traceability management system in the production of power - type slab clamps. The MSC NASTRAN simulation analysis ensures that the product design meets international standards, and the Teamcenter PDM full - process traceability management system enables every production link of the product to be traced, which guarantees product quality and production efficiency.

In conclusion, the power - type slab clamp developed by Dalian Tiding Heavy Industry Co., Ltd. is a revolutionary product in the steel industry. Its technological innovation, adaptability to high - temperature and high - load working conditions, and application advantages in multiple scenarios make it an ideal choice for modern steel enterprises. If you are looking for a high - performance slab clamp to improve your production efficiency and safety, click here to learn more.