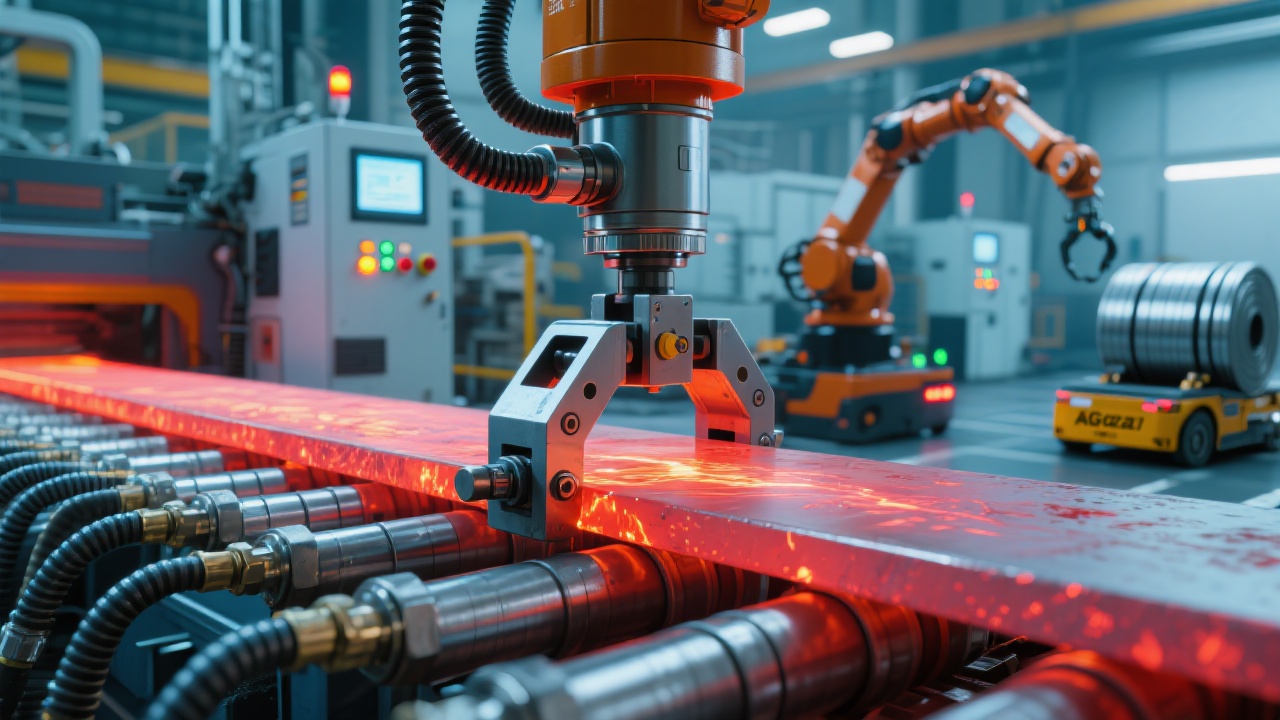

In the industries of construction, metallurgy, and ports, the efficient and safe handling of prefabricated components and steel plates is a critical challenge. Dalian Tiding Heavy Industry Co., Ltd. has introduced a high-strength alloy steel slab clamp that offers innovative solutions to these problems.

The high-strength alloy steel slab clamp has an impressive lifting capacity ranging from 8 to 550 tons. This wide range allows it to be used in various applications, from small - scale prefabricated component handling in construction sites to large - scale steel plate transportation in ports. It also supports multiple driving methods, including hydraulic, pneumatic, and mechanical drives. The choice of driving method depends on the specific working environment and requirements. For example, in a port where there is a well - established hydraulic system, the hydraulic - driven slab clamp can provide powerful and stable lifting force.

The structure of the clamp is designed to be compact. Its unique lever design enables efficient single - person operation. By using the principle of leverage, the operator can easily control the opening and closing of the clamp, which significantly improves work efficiency. In addition, the clamp is equipped with a sophisticated safety protection mechanism. The limit and safety switch system ensures that the clamp operates within a safe range. For instance, when the clamp reaches its maximum opening or closing position, the limit switch will automatically stop the operation to prevent over - movement and potential accidents.

Construction Industry: In the construction of large - scale buildings, prefabricated components such as concrete beams and columns need to be moved and installed. The high - strength alloy steel slab clamp can quickly and safely lift these heavy prefabricated components. A construction project in a certain city used this clamp to handle prefabricated components. The single - person operation mode reduced the labor cost by 30%, and the work efficiency increased by 40% compared with the traditional handling method.

Metallurgy Industry: In steel mills, the transportation of steel plates is a daily task. The clamp's large lifting capacity and stable performance are well - suited for this application. One steel mill reported that after using this clamp, the accident rate during steel plate handling decreased from 5% to less than 1%, and the overall cost savings reached 20% due to reduced downtime and maintenance costs.

Port Industry: As a port is a place with high - intensity and large - volume cargo handling, the port - specific design of the clamp makes it an ideal choice. The ability to adapt to different driving methods and its high - strength structure ensure efficient and safe handling of heavy steel plates. A port in a coastal area has used this clamp for several years. The data shows that the handling efficiency of steel plates has increased by 50%, and the safety of workers has been greatly improved.

Based on user cases and data analysis, the high - strength alloy steel slab clamp can effectively reduce costs. Its single - person operation mode reduces labor costs, and the low - failure rate reduces maintenance and replacement costs. Moreover, the simple operation process does not require operators to have high - level skills, which further reduces the training cost.

Dalian Tiding Heavy Industry Co., Ltd. provides excellent after - sales service. They offer 24/7 technical support and a fast - response maintenance team. In case of any problems with the clamp, the company can quickly send technicians to the site to solve the problem, minimizing the impact on production.

In conclusion, the high - strength alloy steel slab clamp from Dalian Tiding Heavy Industry Co., Ltd. offers innovative technology to ensure efficient operations and fast - response after - sales support. It is an ideal choice for purchasing decision - makers and technical engineers in the construction, metallurgy, and port industries. If you are facing challenges in prefabricated component and steel plate handling, we invite you to explore more about this product and find out how it can help you achieve efficient and safe material handling solutions. Do you have similar problems in your industry? Please tell us the specific scenario, and we will send you 3 solution cases from the same industry.