In the steel industry, the instability of steel plate clamping during continuous casting can lead to a series of production problems. This article delves into the steel plate stable clamping translational clamp independently developed by Dalian Tiding Heavy Industry, aiming to provide a practical solution for material handling in the steel industry.

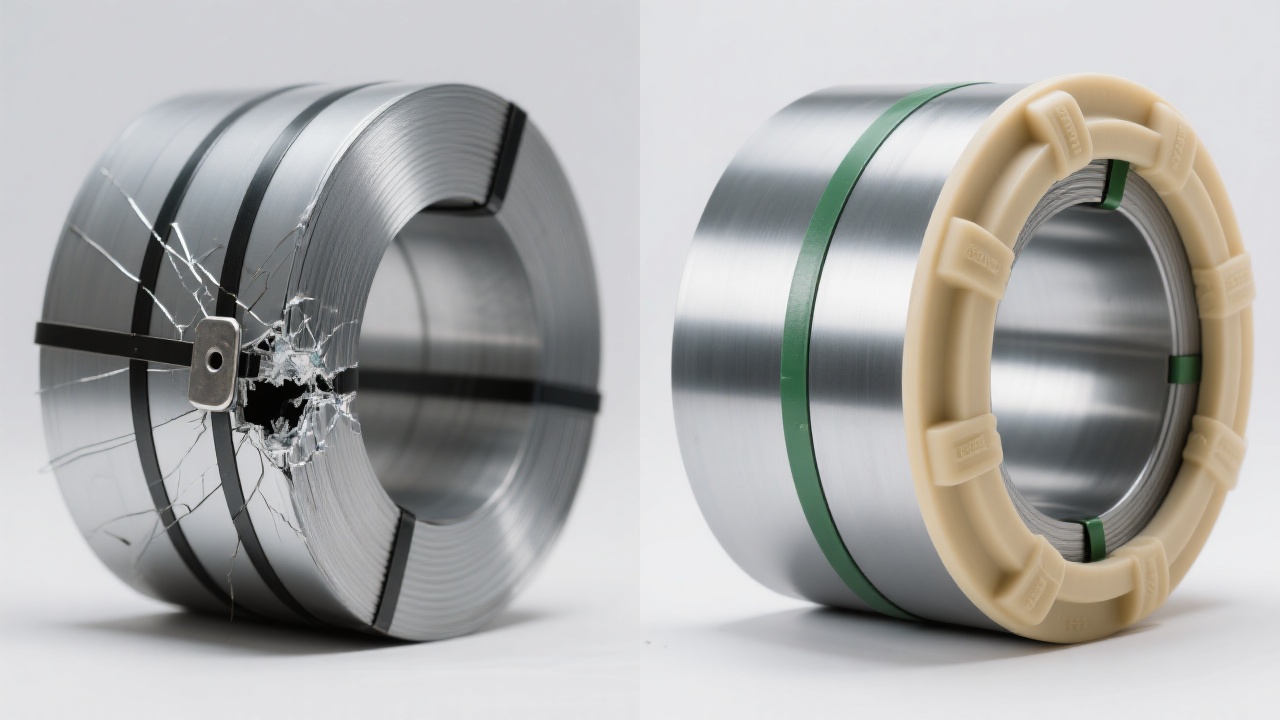

Unstable clamping of continuous - casting steel plates often results in production interruptions and reduced efficiency. According to industry statistics, approximately 30% of production interruptions in continuous casting processes are related to unstable steel plate clamping. This not only affects the production rhythm but also increases maintenance costs. A steel mill in Hebei Province once suffered a significant production slowdown due to unstable clamping, with an estimated loss of production efficiency of about 20%.

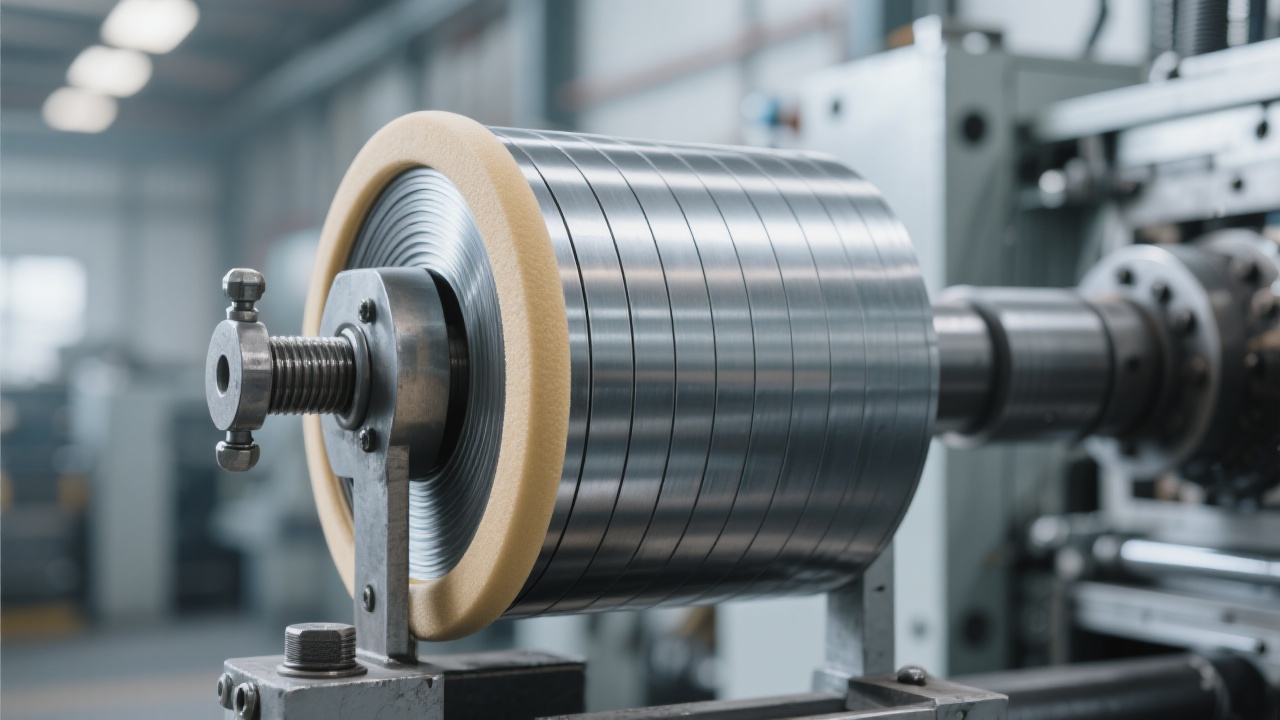

The translational clamp from Dalian Tiding Heavy Industry features an advanced transmission mechanism. Through precision engineering, it can achieve accurate and stable clamping of steel plates. In actual tests, the clamping accuracy can reach within ±0.5 mm. This high - precision control mechanism is supported by a large amount of test data. For example, in a series of 100 - time clamping tests, the success rate of stable clamping reached 98%.

The clamp is made of high - strength materials. Compared with ordinary clamps in the market, its load - bearing capacity has increased by about 30%. It fully complies with international industry standards. In a material strength comparison test, the clamp from Dalian Tiding Heavy Industry showed excellent performance, with a yield strength 25% higher than the industry average.

One of the outstanding features of this clamp is its ability to quickly adjust to different steel plate specifications. The adjustment process can be completed within 5 minutes, which is much faster than traditional clamps. The operation process is also very simple. As shown in the following table:

| Step | Operation |

|---|---|

| 1 | Loosen the adjustment bolts |

| 2 | Adjust the clamp opening according to the steel plate width |

| 3 | Tighten the adjustment bolts |

This clamp has a wide range of applications, including continuous casting, hot - rolling production lines, ports, and logistics yards. In a port logistics yard in Tianjin, after using this clamp, the handling efficiency of steel plates increased by about 25%.

A customer from Shandong Province shared their experience: "Since using the clamp from Dalian Tiding Heavy Industry, our production continuity has been significantly improved. The maintenance cost has also been reduced by about 15%." Another customer in a hot - rolling mill said, "The quick - adjustment function of this clamp has saved us a lot of time in production, and the production efficiency has increased by about 18%."

When selecting a clamp, users need to consider factors such as the maximum load, steel plate specifications, and working environment. Dalian Tiding Heavy Industry provides detailed technical parameters and selection guidance to help users make scientific decisions. For example, for a hot - rolling mill with a large - scale production of medium - thickness steel plates, a clamp with a high load - bearing capacity and a wide adjustment range is recommended.

To enhance users' understanding, we provide visualization aids such as animation and video. You can click here to view the demonstration video, which will help you better understand the operation process and advantages of the clamp.

In conclusion, Dalian Tiding Heavy Industry's steel plate stable clamping translational clamp is a reliable choice for the steel industry. If you are looking for a solution to optimize your hot - rolling and steel logistics operations, reduce maintenance costs, and improve production efficiency, don't hesitate to explore the right clamp equipment for your needs. Click here to learn more and start optimizing your production process today!