Dalian Tiding Heavy Industry Co., Ltd. has been at the forefront of developing high-strength alloy steel slab clamps that offer remarkable performance and reliability. These clamps are designed to meet the demanding needs of various industries, including construction, metallurgy, and ports.

One of the most significant features of these slab clamps is their wide range of lifting capacities, spanning from 8 to 550 tons. This broad capacity spectrum allows the clamps to handle different sizes and weights of steel slabs, making them suitable for a variety of applications. Whether it's a small construction project or a large-scale metallurgical operation, there's a clamp to match the requirements.

Another key advantage lies in the multiple drive modes available. The clamps can be configured with hydraulic, pneumatic, or mechanical drives, providing flexibility in adapting to different working environments and customer preferences. For example, in a port where power sources may be limited, a pneumatic drive can be a practical choice, while in a well - equipped steel mill, a hydraulic drive might offer more precise control.

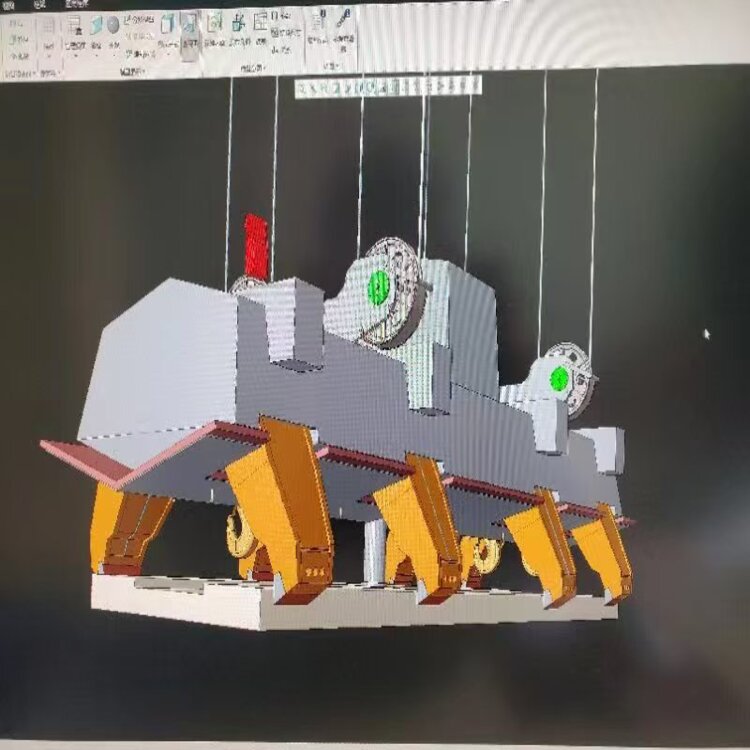

The structural design of the slab clamps is a masterpiece of engineering. They are compact in structure, which not only saves space but also allows for easy installation and operation in confined spaces. The clamping force is extremely stable, thanks to the well - designed clamping mechanism. This stability ensures that the steel slabs are securely held during lifting and transportation, minimizing the risk of accidents.

In addition, the clamps are equipped with safety switch devices. These devices act as a safeguard, automatically shutting down the operation in case of any abnormal conditions, such as over - loading or improper clamping. This feature significantly enhances the safety and reliability of the clamps, protecting both the equipment and the operators.

In the construction industry, the slab clamps play a crucial role in improving the efficiency of building material handling. They can quickly and safely lift and move steel slabs, reducing the time and labor required for manual handling. For example, in a high - rise building project, the clamps can transport large steel slabs to the upper floors in a short time, accelerating the construction progress.

%20Clamp-1.jpg)

In the metallurgical industry, where the working conditions are often harsh and the workload is heavy, the clamps' high - capacity and stable performance are highly valued. They can handle the continuous flow of steel slabs from the production line to the storage area, improving the overall production efficiency and reducing the labor intensity of workers.

At ports, the slab clamps are essential for loading and unloading steel slabs from ships. Their ability to adapt to different drive modes and handle large - scale loads makes them an ideal choice for port operations. They can significantly increase the handling speed, reduce the turnaround time of ships, and improve the overall port productivity.

Dalian Tiding Heavy Industry Co., Ltd. offers excellent after - sales service. All slab clamps come with a one - year warranty, which gives customers peace of mind. In addition, the company provides a 48 - hour rapid response service. If there are any issues with the clamps, the technical support team will be on - site or provide remote assistance within 48 hours to solve the problem, minimizing the downtime of the equipment.

Customer cases have shown that with the use of these slab clamps, companies have achieved significant cost savings and safety management upgrades. For instance, a construction company reported a 30% increase in material handling efficiency and a 20% reduction in labor costs after switching to these clamps.

Are you looking for a reliable and efficient solution for steel slab handling? Click here to learn more about our high - strength alloy steel slab clamps and take your business to the next level!