In the era of Industry 4.0, traditional fixture management methods are facing numerous pain - points. Manual record - keeping and disjointed processes often lead to inefficiencies, such as long lead - times in design changes, difficulty in tracking manufacturing progress, and challenges in maintaining historical data for effective maintenance. For example, in a large - scale steel enterprise, up to 30% of production delays can be attributed to issues in fixture management. This highlights the urgent need for digital transformation to enhance productivity and reduce costs.

The Teamcenter PDM platform plays a central role in the full - lifecycle management of fixtures. In the design phase, it enables seamless collaboration among design teams. Designers can access historical design data, reducing redundant work by up to 40%. During the manufacturing process, the platform allows real - time tracking of production progress. Manufacturers can monitor the status of each fixture, ensuring on - time delivery. In the usage and maintenance stages, it provides a centralized database for storing all relevant information, facilitating quick decision - making when issues arise.

| Lifecycle Stage | Function of Teamcenter PDM |

|---|---|

| Design | Collaboration, access to historical data |

| Manufacturing | Progress tracking |

| Usage | Centralized data storage |

| Maintenance | Quick decision - making support |

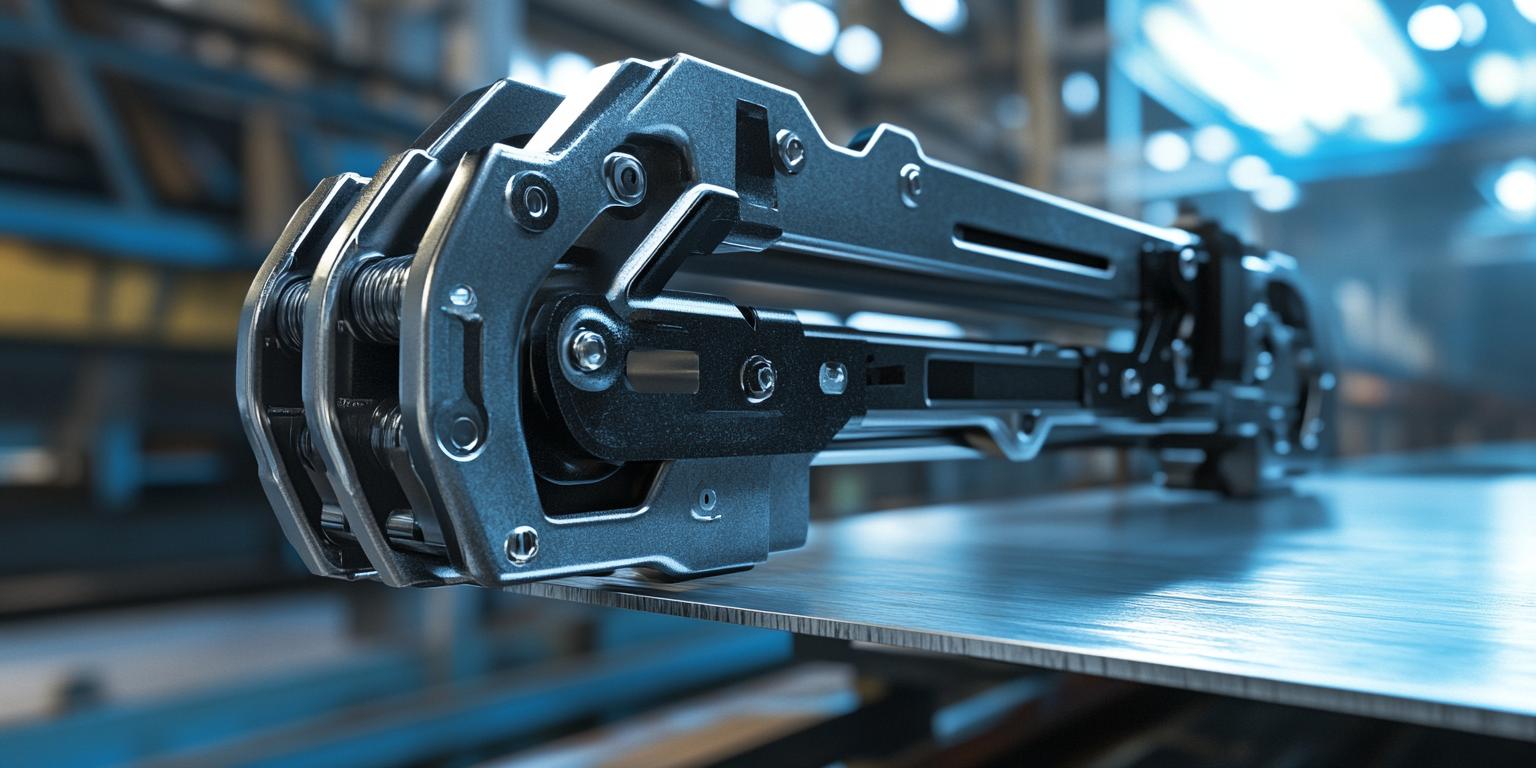

For fixtures operating in extreme environments, such as high - temperature conditions in steel plants, the MSC NASTRAN simulation is crucial. It can accurately predict the structural strength and thermal deformation behavior of fixtures. By running simulations, engineers can identify potential weak points in the design and make necessary adjustments before production. This not only ensures the stable operation of fixtures in extreme environments but also extends their service life by up to 20%.

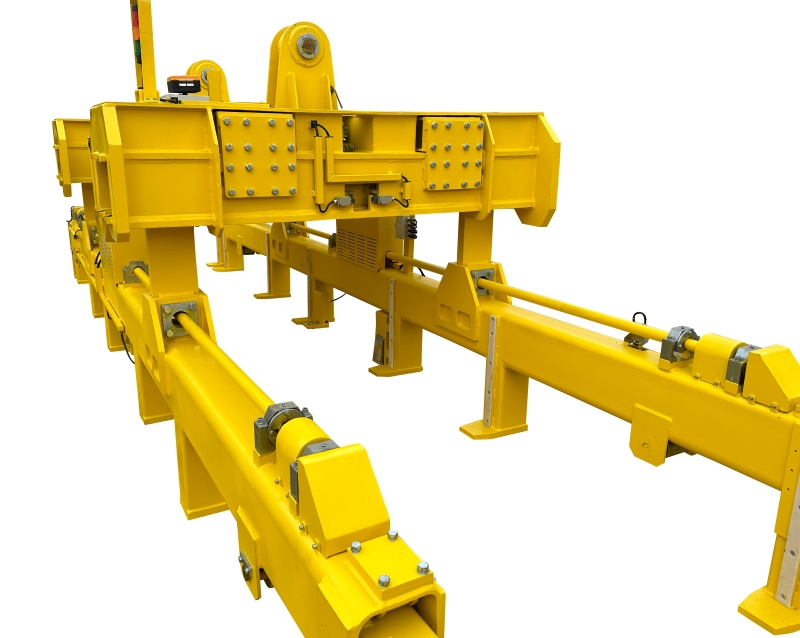

With over 1100+ sets of fixture deliveries, Dalian Tiding Heavy Industry has accumulated a large amount of data. This data is used for continuous quality improvement. By analyzing production and usage data, the company can identify common issues and develop standardized solutions. The construction of a standardized knowledge base enables new employees to quickly learn from past experiences, reducing the learning curve by up to 50%.

The future of fixture management lies in intelligent maintenance. With the development of the Internet of Things (IoT) and artificial intelligence, fixtures will be able to self - diagnose problems and send maintenance alerts in real - time. Enterprises should start preparing for this trend by investing in relevant technologies and training their staff. By implementing digital fixture management solutions, they can make each clamp a traceable, optimizable, and inheritable intelligent asset.

Is your fixture management already digitalized? If not, it's time to take action and embrace the benefits of Industry 4.0!