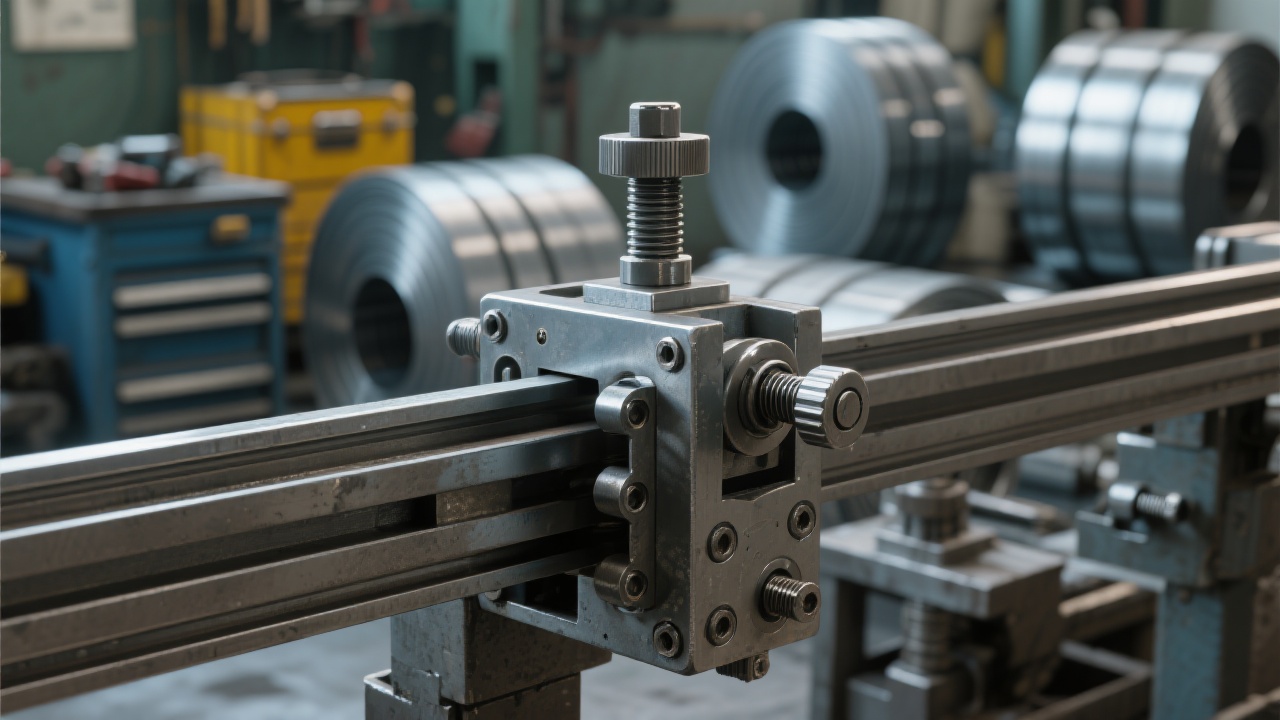

In the modern steel industry, the integration of automated clamps with PLC and robotic handling systems has become a crucial technology for enhancing production line automation and operational safety. This article delves into the practical aspects of this integration, providing a comprehensive guide for steel industry users.

The automated clamps play a vital role in hot - rolling production lines. Their integration with PLC control systems, robotic handling systems, and AGV carts is essential for seamless operation. The first step in this integration is the configuration of signal interfaces. The signal interfaces between the pneumatic clamps, PLC, and other systems need to be carefully designed to ensure accurate data transmission. For example, the input and output signals of the pneumatic clamps should be clearly defined, and the communication protocols should be compatible with the PLC and other connected devices.

The action sequence logic setting is another key aspect. The movement of the clamps, such as opening, closing, and holding, should be precisely timed to match the overall production process. This involves programming the PLC to control the clamps' actions according to specific events and conditions. For instance, the clamp should open when the AGV cart arrives at the designated position and close when it is ready to pick up the workpiece.

Safety is of utmost importance in the operation of automated clamps. The safety interlock mechanism is designed to prevent potential accidents and ensure the reliable operation of the system. The design concept of the safety interlock mechanism is based on the principle of multiple levels of protection. For example, when the clamp is in operation, it should be interlocked with other components of the system to prevent any unexpected movements.

To implement the safety interlock mechanism, several methods can be used. One common method is to use sensors and switches to detect the status of the clamps and other devices. These sensors can send signals to the PLC, which then controls the actions of the clamps based on the received information. For example, if the limit switch detects that the clamp has reached its maximum or minimum position, the PLC will stop the corresponding movement to prevent over - travel.

On - site installation and commissioning are critical steps in ensuring the proper operation of the automated clamp system. Gas source pressure matching is a crucial factor. The pressure of the gas source should be adjusted to match the requirements of the pneumatic clamps. If the pressure is too high, it may cause damage to the clamps; if the pressure is too low, the clamps may not operate properly.

Limit switch calibration is also essential. The limit switches need to be accurately calibrated to ensure that they can detect the position of the clamps correctly. Anti - jitter measures should be taken to prevent false signals caused by vibration or other factors. For example, using software algorithms or hardware filters can effectively reduce the impact of jitter.

Through real - world case studies, we can see the practical benefits of integrating automated clamps in hot - rolling production lines. In one case, a steel company integrated automated clamps with their existing robotic handling system. By optimizing the signal interface configuration and action sequence logic, they were able to increase the production efficiency by 30% and reduce the accident rate by 40%. This shows that proper integration can significantly improve the performance of the production line.

Industry best practices also provide valuable insights. For example, some companies use standardized procedures for on - site installation and commissioning, which can reduce the installation time and improve the reliability of the system. They also regularly update the software of the PLC and other control systems to keep up with the latest technological developments.

The integration of automated clamps with PLC and robotic handling systems offers significant advantages for the steel industry, including increased production efficiency, enhanced safety, and improved equipment stability. By following the guidelines in this article, steel industry users can quickly master the integration technology and take their production lines to the next level.

If you are looking to enhance your steel production line's automation and safety, click here to learn more about our automated clamp integration solutions.