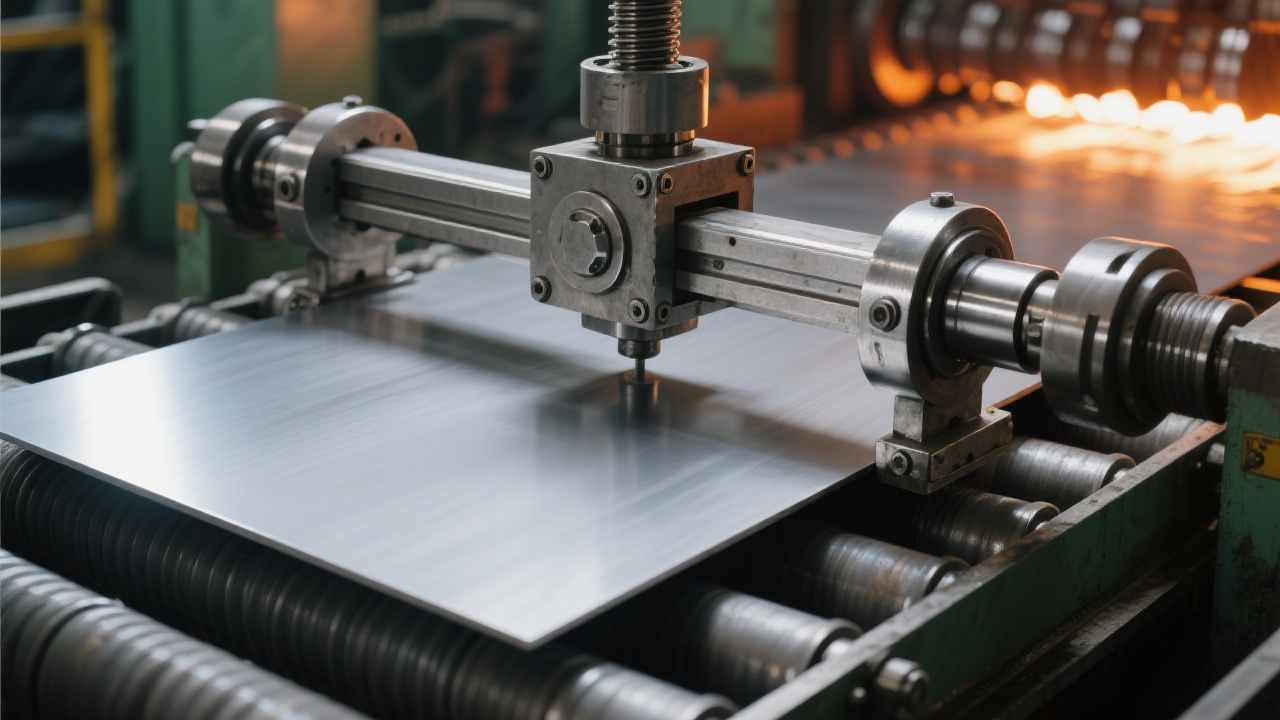

In the realm of industrial manufacturing, the reliability of equipment structures is of paramount importance. Dalian Tiding Heavy Industry has taken a significant step forward in this area with its independently developed industrial-grade slab transfer clamps. This article delves into how the company uses MSC NASTRAN finite element simulation technology to enhance the precision and reliability of clamp structure design, combined with PDM system data management to ensure product quality.

Finite element simulation is a powerful tool in modern engineering design. For Dalian Tiding's industrial clamps, MSC NASTRAN finite element simulation technology is used to analyze the load and stress distribution of the clamp. By simulating various high - load working conditions, engineers can accurately predict how the clamp will perform under real - world scenarios. For example, through load simulation, they can determine the maximum load the clamp can bear, and stress distribution analysis helps to identify potential weak points in the structure. This is crucial for ensuring the stable operation of the clamp in high - load environments.

In addition to finite element simulation, Dalian Tiding also uses the PDM (Product Data Management) system for full - process data management and quality control. The PDM system integrates all aspects of the product life cycle, from design and simulation to manufacturing. It ensures that every step of the process is traceable and controllable. For instance, during the design phase, engineers can record all design parameters in the PDM system. During the simulation phase, the simulation results are also stored in the system for further analysis and comparison. In the manufacturing phase, the system can monitor the production process to ensure that the final product meets the design requirements. This comprehensive quality control mechanism has been verified by more than 1100 sets of clamps in long - term operation.

The real - world operation data and user feedback of over 1100 sets of clamps have verified the results of structural optimization. Through continuous improvement of the clamp structure, the failure rate has been significantly reduced. For example, the original failure rate of the clamp might have been around 5%, but after structural optimization, it has dropped to less than 1%. Moreover, the service life of the clamp has been extended. A well - optimized clamp can operate stably for more than 10 years, which is a significant advantage in the industrial market.

This article provides a practical evaluation framework for users to scientifically evaluate the reliability of industrial clamps. It includes steps such as load simulation, stress analysis, and data management. By following this framework, users can make more informed decisions when selecting and maintaining industrial clamps. For example, they can use finite element simulation to evaluate the load - bearing capacity of a clamp before purchasing, and use the PDM system to manage the product data during the operation process.

In conclusion, Dalian Tiding's industrial clamps, with the support of MSC NASTRAN finite element simulation technology and PDM system data management, offer high reliability and long - term stability. For industries that require high - quality industrial clamps, such as steel manufacturing, heavy machinery, and logistics, these clamps are an ideal choice. Click here to learn more about how our clamps can meet your needs and drive your智能制造升级!