Selecting the right hydraulic-driven slab clamp isn’t just about lifting capacity—it’s about safety, efficiency, and long-term operational stability in high-stress environments like steel mills and port terminals. With lifting capacities ranging from 8 to 550 tons, modern clamps must balance power with precision, especially when handling hot or cold slabs that demand consistent grip and minimal risk of slippage.

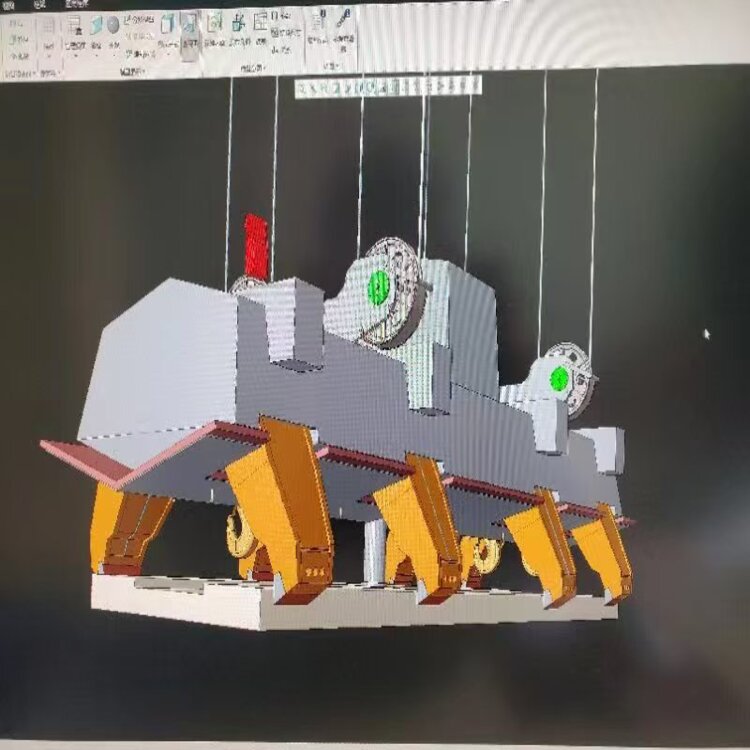

Titan Ding Heavy Industry’s alloy steel slab clamps are engineered for extreme conditions. Their multi-drive system (single, dual, or triple hydraulic actuation) ensures even pressure distribution across the clamp jaws—critical for preventing deformation during transport. Unlike traditional single-point designs, this setup reduces wear on both the clamp and the slab surface by up to 35%, according to field tests conducted at three major Chinese steel plants.

| Feature | Benefit |

|---|---|

| Leverage-Based Design | Reduces manual effort by 40% while increasing torque accuracy |

| Integrated Limit Switches | Prevents over-extension, reducing mechanical stress by 60% |

| Safety Lock Mechanism | Ensures zero accidental release—even under vibration or sudden stop |

At a port facility in Rotterdam, Titan Ding clamps were tested against legacy models during peak container loading hours. The result? A 27% increase in daily throughput and zero incidents related to load instability over a six-month period. Similarly, in a steel mill in Brazil, operators reported a 30% reduction in maintenance downtime thanks to the clamp’s sealed hydraulic system and corrosion-resistant coating.

What sets these clamps apart is not just their build quality—but how they’re supported. Titan Ding offers a 48-hour response time for technical queries, plus a comprehensive 2-year warranty covering all core components. This level of service builds trust faster than any brochure ever could.

Whether you're managing concrete precast logistics or optimizing slab handling in a busy steel plant, choosing the right hydraulic clamp is one of the smartest investments you’ll make this year. It’s not just about moving metal—it’s about building confidence in every lift.

Ready to upgrade your material handling operations?

Get a free technical consultation tailored to your site conditions — no obligation, just real solutions.

Request Your Customized Solution Now