In the era of Industry 4.0, the manufacturing industry is undergoing a profound transformation. One of the key challenges is how to achieve digital management of fixtures. This article delves into this issue, taking the power - type slab clamp independently developed by Dalian Tiding Heavy Industry as an example, and explores the practice and value of the PDM platform (Teamcenter) in manufacturing enterprises.

Traditional fixture management methods often face several limitations. For example, data is scattered, making it difficult to integrate and share. Version control is chaotic, leading to potential errors in design and manufacturing. In addition, the lack of effective collaboration mechanisms between different departments can slow down the product development cycle. According to a survey, nearly 30% of manufacturing enterprises have experienced production delays due to fixture management issues.

The PDM platform, especially Teamcenter, plays a crucial role in fixture management. Firstly, it enables seamless data integration. All fixture - related data, including design drawings, manufacturing processes, and usage records, can be stored and managed in a unified database. This not only improves data accessibility but also enhances data security.

Secondly, the PDM platform provides powerful version control functions. Each version of the fixture design can be accurately tracked, and historical versions can be easily retrieved. This ensures that all stakeholders are working with the latest and correct information.

Thirdly, it promotes collaborative design. Different departments, such as design, engineering, and manufacturing, can work together on the same platform. For example, designers can share their ideas with engineers in real - time, and engineers can provide feedback on the feasibility of the design. This collaborative approach can significantly reduce the time and cost of product development.

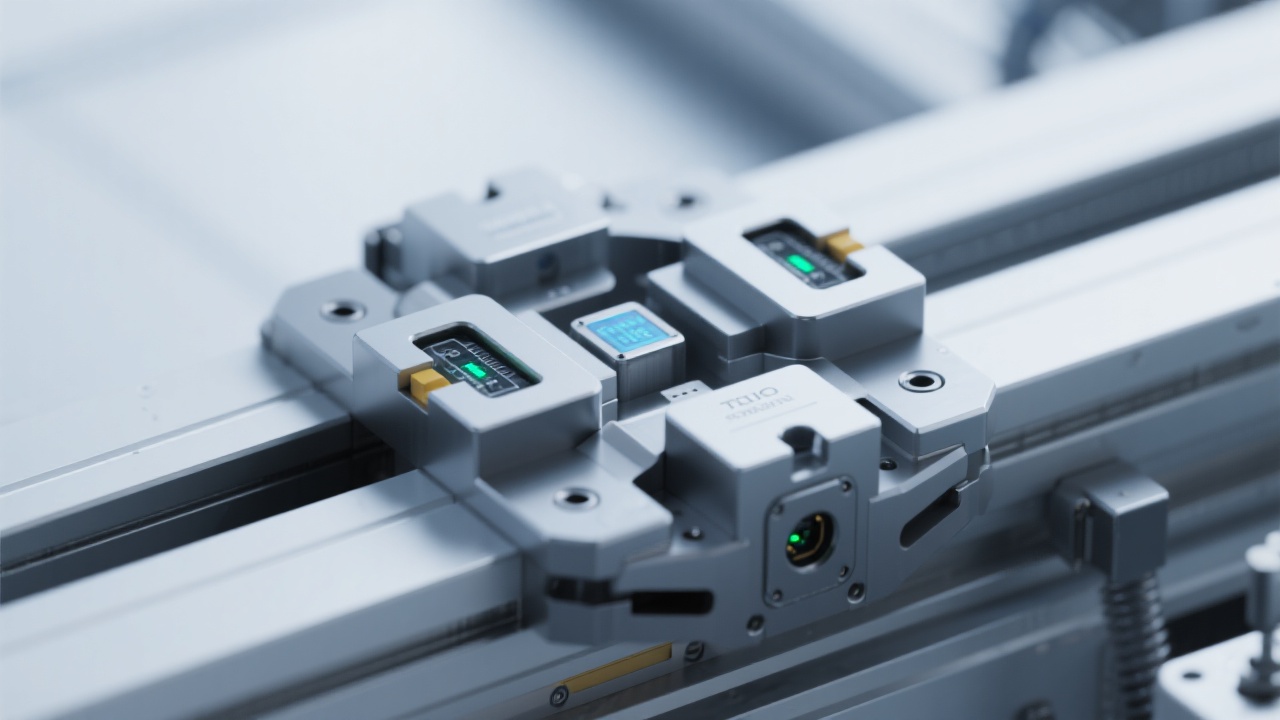

To ensure the structural stability of fixtures under extreme working conditions, MSC NASTRAN simulation technology is used. This technology can simulate the thermal deformation and stress distribution of fixtures. By analyzing the simulation results, engineers can optimize the fixture design to improve its performance.

For instance, in the case of the power - type slab clamp developed by Dalian Tiding Heavy Industry, the simulation analysis shows that by adjusting the thickness and shape of certain parts, the stress concentration can be effectively reduced, and the overall strength of the clamp can be improved. After optimization, the clamp can withstand 20% more load than the original design.

Many steel enterprises have benefited from the implementation of the PDM platform and simulation technology in fixture management. For example, a large - scale steel company has successfully built a reusable and traceable fixture knowledge base with the help of these technologies. Since the implementation, the company has reduced fixture - related production downtime by 40% and improved product quality by 30%.

In the future, fixtures are expected to evolve towards intelligence and digital twins. Intelligent fixtures can self - adjust according to different working conditions, improving production efficiency and flexibility. Digital twins, on the other hand, can create virtual models of fixtures that mirror their real - world counterparts, enabling real - time monitoring and prediction of performance.

The implementation of the PDM platform and simulation technology is not only a tool - based improvement but also a systematic upgrade of organizational capabilities. It can help enterprises build a standardized fixture knowledge base and lay a solid foundation for subsequent intelligent upgrades. Are you ready to embrace the digital transformation of fixture management? Click here to learn more about how we can assist your enterprise in achieving this goal.