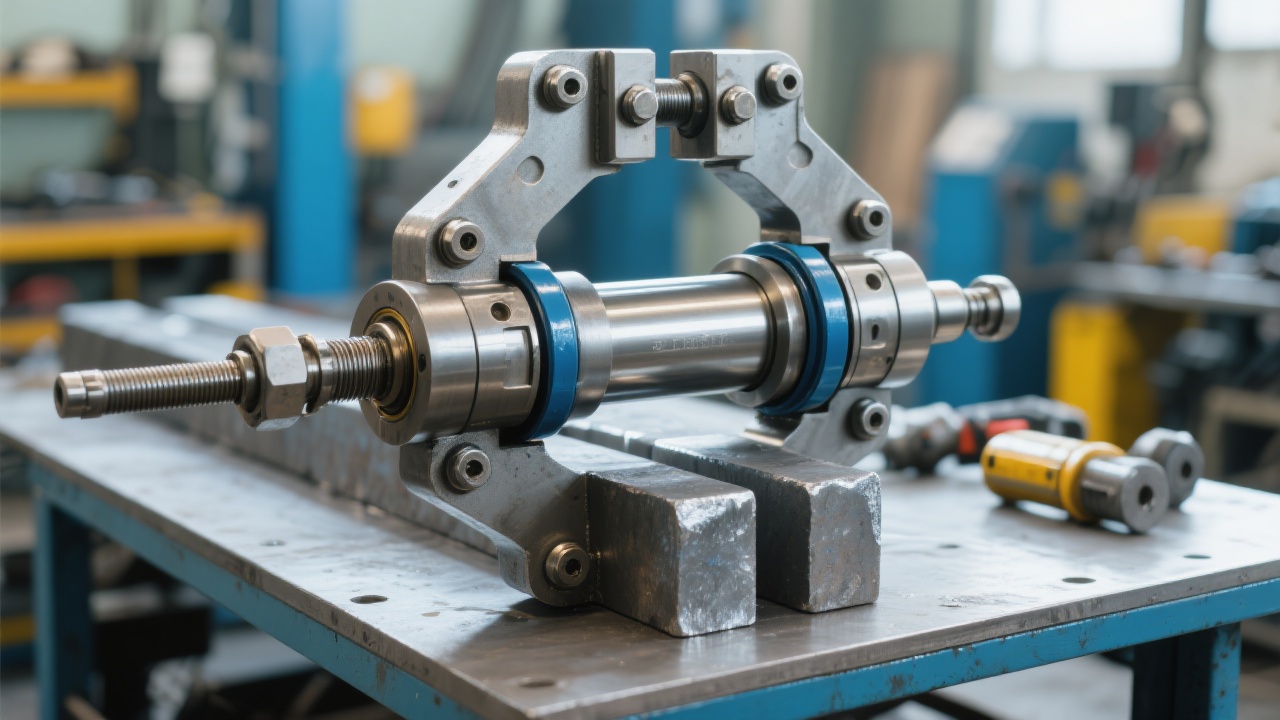

In the high-stakes environment of steel manufacturing, where temperatures exceed 1,200°C and production lines run 24/7, traditional plate clamps often fail under stress—leading to downtime, safety risks, and inefficiencies. At Dalian Tideng Heavy Industry, we’ve engineered a new generation of power plate clamps that don’t just survive these conditions—they thrive.

Our key breakthrough lies in two areas:

Unlike older mechanical clamps that rely on fixed pressure settings, our system uses embedded sensors and a PID-controlled actuator to modulate clamp force within ±3% tolerance across varying slab weights—from 10 tons to 35 tons.

| Feature | Traditional Clamp | Tideng Power Clamp |

|---|---|---|

| Max Operating Temp | ~600°C | ~850°C |

| Clamp Force Stability | ±15% | ±3% |

| Maintenance Interval | Every 3 months | Every 9–12 months |

We tested this system in two critical applications:

Cold Rolling Line (South Korea): Before installation, operators reported frequent slippage during pick-up from reheating furnaces due to uneven thermal expansion. After switching to our clamp, scrap rate dropped from 2.3% to 0.7% in three months—a savings of ~$42,000/month in raw material costs.

Logistics Transfer (Mexico): In a logistics center handling 1,200 slabs/day, the old clamps required 3 operator interventions per shift for alignment correction. With our smart hydraulics, those dropped to zero—boosting throughput by 18% without adding labor or equipment.

Each clamp is equipped with an RFID tag and linked to a cloud-based tracking system. From factory QA tests to on-site performance logs—including temperature cycles, cycle counts, and maintenance history—you get full transparency. This isn’t just compliance—it’s a competitive edge in ISO 9001 and CE-certified plants worldwide.

In fact, one European customer said it helped them pass their annual audit with zero non-conformities—an outcome rarely achieved with conventional tools.

If you're managing a steel plant where automation efficiency directly impacts profitability, it’s time to rethink your clamping strategy. Don’t settle for "good enough"—upgrade to a system built for precision, durability, and intelligent operation.