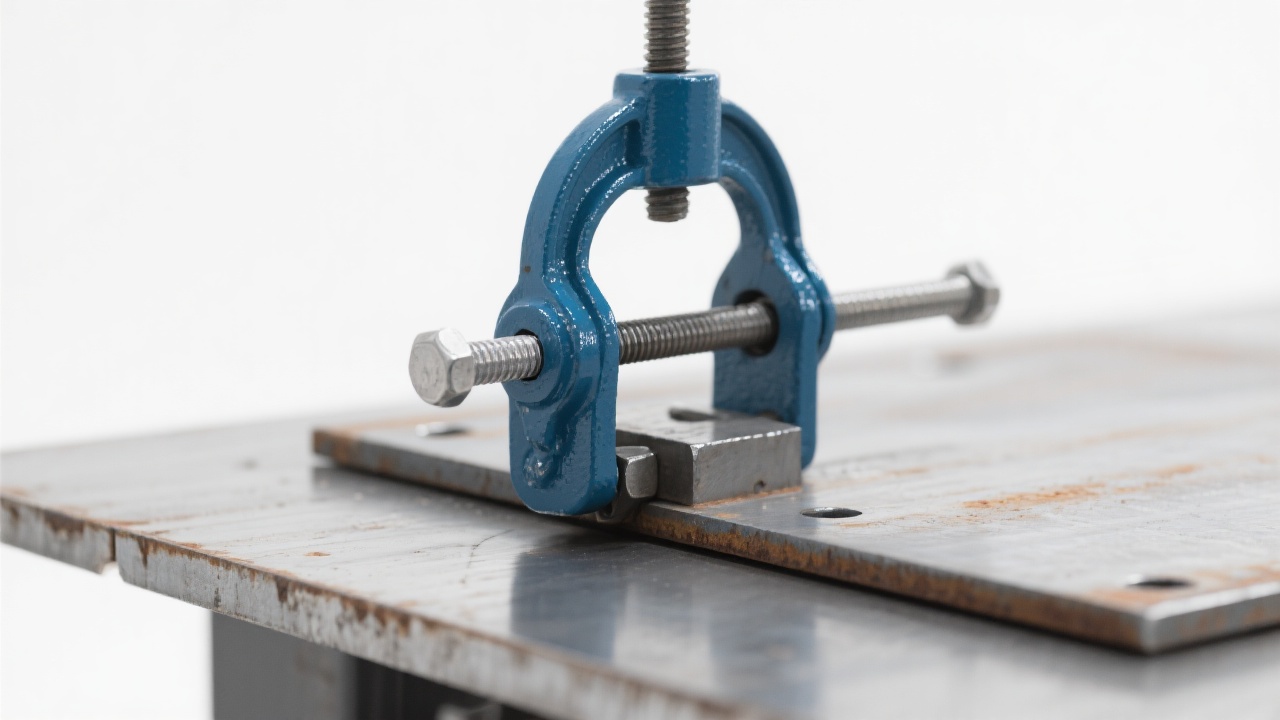

In the steel manufacturing industry, integrating automation into hot rolling lines is no longer optional—it’s a necessity for efficiency, safety, and consistency. At Dalian Tiding Heavy Industry, we’ve developed a robust pneumatic plate billet clamp system designed specifically for high-temperature environments. This guide walks you through real-world integration steps using PLC logic, signal mapping, and safety interlocks—based on over 18 years of cross-industry B2B automation experience.

When connecting your PLC (e.g., Siemens S7-1200 or Allen-Bradley CompactLogix) to the pneumatic clamp, start by defining input/output signals:

| Signal Type | Function | Example I/O Address |

|---|---|---|

| Digital Input | Clamp Open/Close Position Detection | I0.0 / I0.1 |

| Digital Output | Pneumatic Valve Control (Clamp Actuation) | Q0.0 / Q0.1 |

| Analog Input | Air Pressure Monitoring (0–10V) | AI0.0 |

For reliable operation in temperatures up to 500°C, ensure that all sensors are rated IP67 and use shielded cables to minimize EMI interference—a common issue in mill environments.

A well-designed safety interlock can reduce unplanned downtime by up to 40% (per a 2023 study from the Iron & Steel Institute). Key elements include:

A Tier-1 automotive steel supplier in Duisburg faced repeated misalignment issues during AGV-to-robot handoff. By implementing our clamp integration protocol—including precise limit switch calibration (±0.5 mm tolerance), anti-vibration mounting brackets, and a 3-second debounce timer in the PLC logic—they reduced scrap rate by 18% within two months.

Key takeaway: It’s not just about connecting wires—it’s about designing for real-world variability. Our clients report an average ROI of 6–9 months post-integration, especially when paired with predictive maintenance strategies.

Ready to boost your hot strip mill automation? Whether you're integrating with robots, AGVs, or legacy systems, we provide technical documentation, code templates, and remote support to ensure smooth deployment.

Download the Full Integration Checklist Now