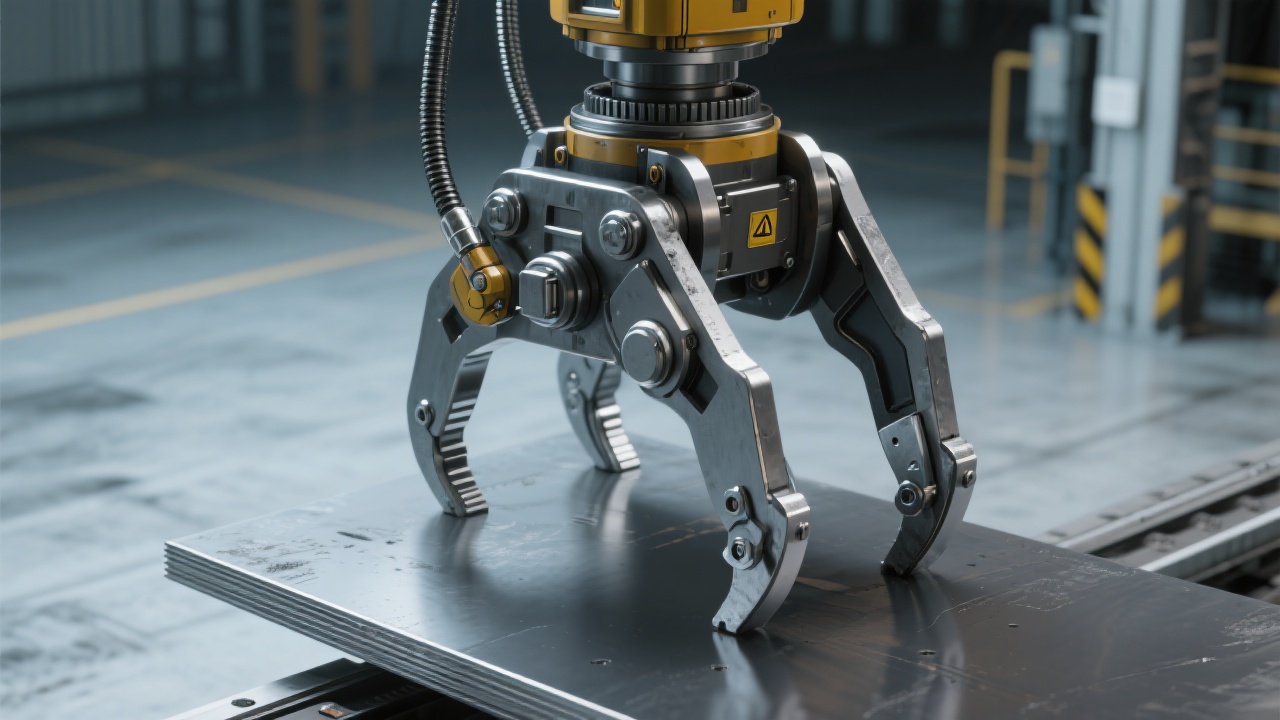

In the demanding environments of ports, steel mills, and construction sites, reliable lifting equipment is not just an asset—it’s a necessity. At Dalian Tiding Heavy Industry Co., Ltd., we’ve engineered a new standard in heavy-duty clamping technology: the High-Strength Alloy Steel Billet Clamp, designed for capacities ranging from 8 to 550 tons with multiple drive options and intelligent safety features.

Our clamps are built for real-world conditions—not just lab tests. Each model undergoes rigorous load testing at 125% of rated capacity, ensuring consistent performance under stress. For example:

| Capacity Range | Drive Type | Avg. Cycle Time per Lift | Safety Margin (Tested) |

|---|---|---|---|

| 8–100 tons | Hydraulic | 15–20 seconds | 125% |

| 100–550 tons | Electric + Hydraulic Hybrid | 25–35 seconds | 130% |

Unlike generic lifting tools, our clamp integrates three critical innovations:

These features were validated through field trials at a major port in Qingdao, where downtime due to clamp-related incidents dropped by 76% within six months of deployment.

Whether you're handling hot rolled coils in a metallurgical plant or stacking rebar on a coastal construction site, this clamp adapts seamlessly:

Port Operations: One client in Dubai reported a 30% increase in daily cargo turnover after switching to our hybrid-drive clamp—thanks to faster cycle times and reduced manual intervention.

Construction Sites: A contractor in Houston used the clamp for lifting precast concrete beams. With zero incidents over 12 months, their OSHA compliance score improved significantly.

Steel Mills: In India, a mill operator saw a 40% reduction in maintenance costs because of the clamp’s durable alloy composition and sealed internal mechanisms that resist corrosion from high-temperature environments.

What truly sets us apart? It’s not just the hardware—it’s how we support it. Our global service network ensures response times under 4 hours for urgent technical queries, and we offer free remote diagnostics via IoT-enabled sensors embedded in each clamp.

If your team spends too much time troubleshooting unstable lifts or worrying about safety compliance, it’s time to rethink your tooling strategy.

“We don’t sell clamps—we deliver confidence in every lift.”

Get Your Free Technical Brochure & Case Study Pack →What’s your biggest challenge when it comes to material handling? Let us know in our quick survey—we’ll tailor future content based on your input.