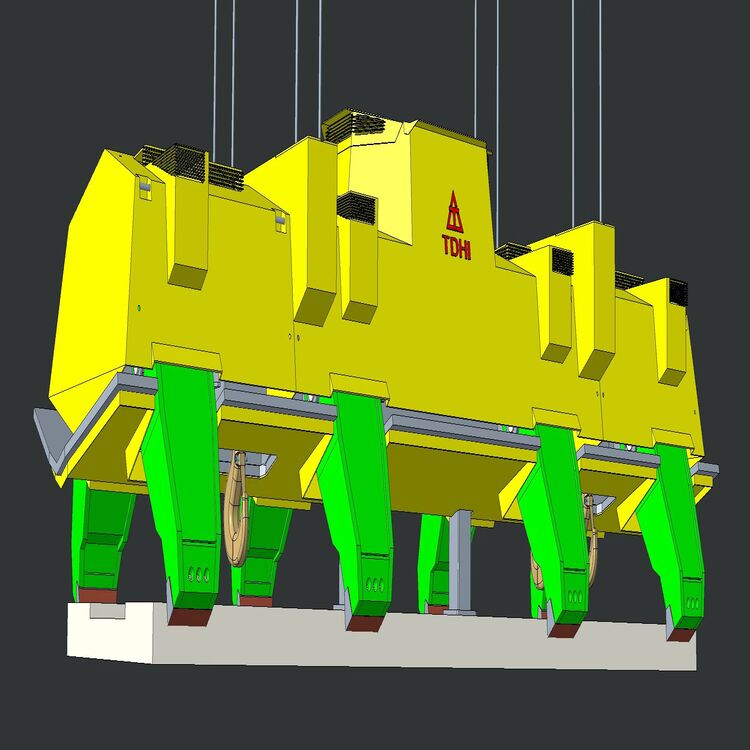

Dalian Tiding Heavy Industry's high-strength alloy steel slab tongs are a revolutionary product in the field of heavy lifting. These tongs are designed to handle a wide range of weights, from 8 tons to an impressive 550 tons. This wide weight capacity range makes them suitable for various applications in the construction, metallurgy, and port industries.

The slab tongs support multiple drive methods, including hydraulic and mechanical drives. Hydraulic drive offers precise control and high power, which can significantly improve the efficiency of lifting operations. For example, in a large - scale steel mill, the hydraulic - driven slab tongs can lift heavy steel plates quickly and smoothly, reducing the time required for each lifting cycle by up to 30% compared to traditional equipment.

In terms of safety design, the tongs are equipped with advanced locking mechanisms and overload protection devices. The locking mechanism ensures that the slab is securely held during lifting, even in the event of sudden power failure or other emergencies. The overload protection device can automatically stop the lifting operation when the weight exceeds the rated capacity, preventing potential accidents and protecting both the equipment and the operators.

The hydraulic drive mode provides smooth and stable lifting force. It can adapt to different working conditions and load requirements. In the construction of high - rise buildings, the hydraulic - driven slab tongs can precisely place pre - cast concrete components, improving the accuracy of construction and reducing the risk of component damage. The hydraulic system also allows for easy adjustment of the clamping force, ensuring a firm grip on the slab.

Mechanical drive is known for its reliability and simplicity. It is suitable for environments where the power supply is unstable or where a more straightforward operation is required. In some small - to - medium - sized steel plants, mechanical - driven slab tongs are widely used due to their low maintenance requirements and long service life.

A construction company was facing challenges in transporting large pre - cast concrete components. The traditional lifting equipment was slow and prone to damage the components. After using Tiding's high - strength alloy steel slab tongs, the company saw a significant improvement in efficiency. The tongs' precise clamping and stable lifting reduced the damage rate of components from 10% to less than 2%, saving a large amount of cost on component replacement.

In a large steel mill, the transportation of steel plates was a time - consuming and labor - intensive process. The Tiding slab tongs with hydraulic drive were introduced, and they increased the daily steel plate transfer volume by 40%. The advanced safety features also reduced the number of accidents in the steel plate transfer process, improving the overall working environment.

At a busy port, the handling of various heavy cargos was a complex task. The port adopted Tiding's port - specific slab tongs, which were able to handle different types of cargos efficiently. The multi - drive mode and high - capacity design allowed for quick loading and unloading of ships, reducing the ship's berthing time by up to 20% and increasing the port's throughput.

%20Clamp-1.jpg)

Tiding Heavy Industry provides a comprehensive quality assurance system. All slab tongs undergo strict quality inspections before leaving the factory. In addition, the company offers a fast after - sales response service. If there is any problem with the equipment, the technical support team can be on - site within 24 hours in most regions, ensuring minimal downtime for the customers.

If you are a procurement decision - maker or a technical professional looking for advanced lifting equipment, don't miss out on the opportunity to explore Tiding's high - strength alloy steel slab tongs. Click here to learn more and make the right choice for your business!