In today’s competitive steel production environment, every second of downtime costs thousands of dollars—and a single faulty plate clamp can disrupt an entire rolling mill shift. That’s why leading manufacturers are turning to digital lifecycle management for industrial fixtures like Dalian Tiding Heavy Industry’s power plate clamps. By integrating simulation tools such as MSC NASTRAN with enterprise PDM platforms like Teamcenter, companies now achieve unprecedented precision in tracking design specs, usage patterns, and maintenance history across the full life cycle of each fixture.

According to a 2023 McKinsey study, plants using digital twin technology for tooling saw a 17% reduction in unplanned downtime and a 12% improvement in overall equipment effectiveness (OEE). For high-temperature applications—like those found in continuous casting lines where temperatures exceed 1,200°C—this level of visibility isn’t just helpful; it’s essential.

| Stage | Key Metrics Improved | Avg. ROI Timeframe |

|---|---|---|

| Design | Reduced rework by 28% | 6–9 months |

| Manufacturing | Improved tolerance consistency by 35% | 4–6 months |

| Maintenance | Predictive failure alerts reduced repair time by 40% | 3–5 months |

At one major Chinese steel plant, engineers used MSC NASTRAN to simulate thermal deformation under extreme conditions. The results showed that traditional designs failed at 950°C due to uneven stress distribution—but after redesigning based on simulation data, the new titanium-alloy plate clamp maintained structural integrity up to 1,250°C. This wasn’t just theory—it translated into a 30% decrease in clamp-related failures over six months.

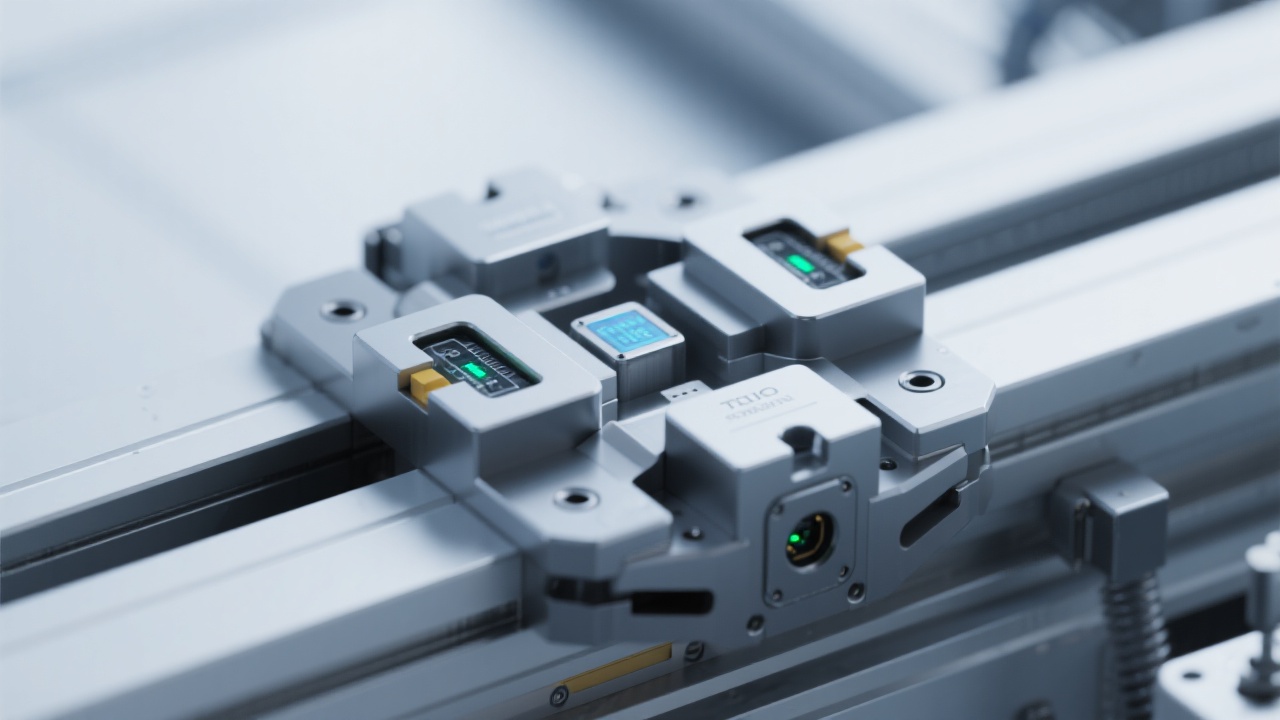

Meanwhile, Teamcenter enabled seamless integration between R&D, procurement, and field service teams. Each clamp now has a unique ID tied to its manufacturing batch, test logs, and even operator feedback. This creates a living knowledge base—not just a database—that grows smarter with every use.

As one operations manager from a Middle Eastern steel producer put it: “Before we implemented this system, we were guessing when to replace clamps. Now, we know exactly when they need attention—before they fail.”

For B2B buyers looking to reduce waste, improve safety, and future-proof their operations, adopting a structured approach to fixture lifecycle management is no longer optional—it’s strategic.

“The next generation of industrial automation won’t be built on machines alone—it’ll be powered by data from every tool on the floor.”

— Dr. Li Wei, Senior Engineer, Dalian Tiding Heavy Industry

Ready to transform how your team manages industrial fixtures?

Discover how our smart clamping solutions integrate with your existing systems to deliver real-time insights and long-term cost savings.

Explore Our Smart Clamp Solutions Today