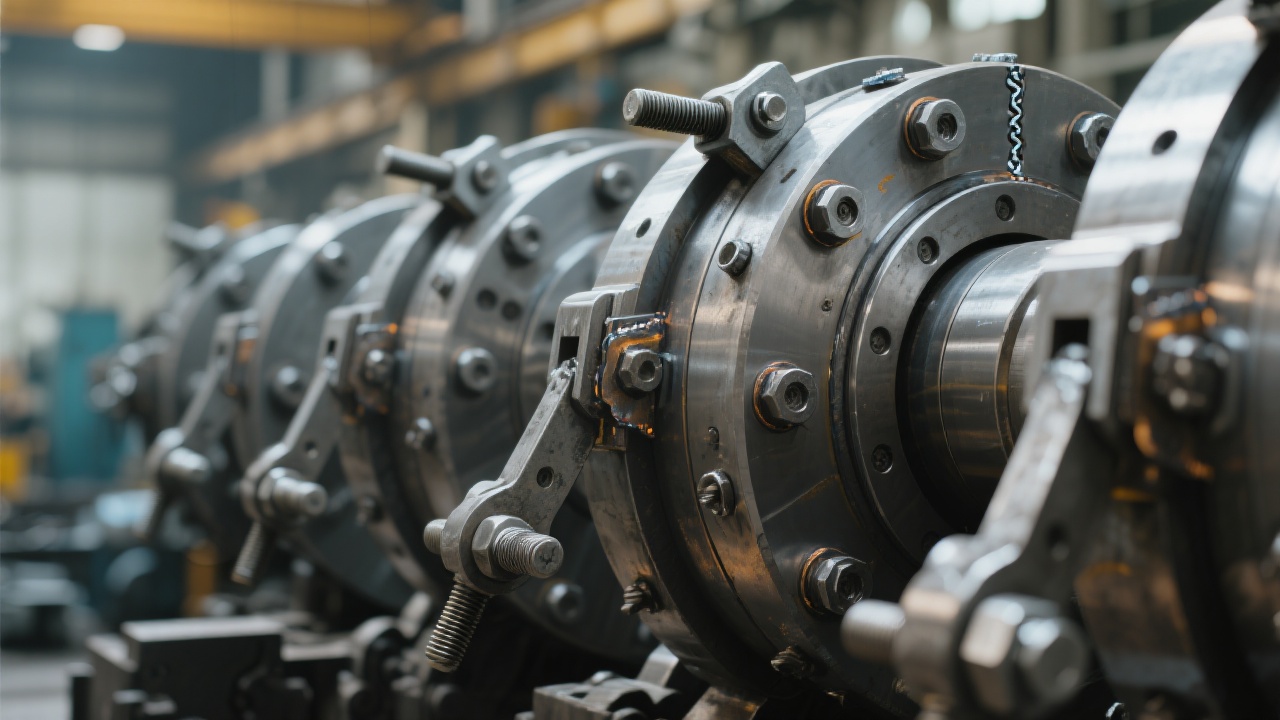

In today’s steel manufacturing landscape, efficiency and safety are no longer optional—they’re survival essentials. Traditional plate billet clamps often fail under the extreme conditions of hot rolling lines, leading to unexpected downtime, maintenance costs, and even safety risks. At Dalian Tiding Heavy Industry, we’ve addressed this challenge head-on with our powered plate billet clamp, engineered for sustained performance in high-temperature, high-load environments.

Industry data shows that traditional hydraulic clamps experience an average failure rate of 1.8 times per month in continuous casting and cold rolling operations—mainly due to thermal deformation and mechanical fatigue. In one case study at a mid-sized Chinese steel mill, a single clamp failure caused a 4.2-hour production halt, costing over $12,000 in lost output and labor.

| Clamp Type | Avg. Monthly Failures | Temp Range (°C) |

|---|---|---|

| Standard Clamp | 1.8 | ≤ 600°C |

| Tiding Powered Clamp | 0.2 | ≥ 800°C |

Our powered clamp leverages two core innovations:

A customer in South Korea reported a 27% increase in handling speed after switching to our clamp during cold finishing operations—a result directly tied to reduced setup time and fewer misalignments.

Quality isn’t just about materials—it’s about consistency. Every unit undergoes full lifecycle tracking via Teamcenter PDM software, ensuring every weld, bolt torque, and test result is documented and retrievable. This means faster root cause analysis when issues arise—and stronger compliance with ISO 9001 and CE standards.

“We used to lose 3–5 hours per week to clamp-related stoppages. Now, with Tiding’s solution, it’s less than 30 minutes.”

— Zhang Wei, Maintenance Manager, Shandong Steel Co.

For engineers, procurement teams, and plant managers looking to reduce risk while boosting throughput, this isn’t just another product—it’s a proven upgrade path.

See How Our Clamp Performed in Your Plant – Request a Case Study