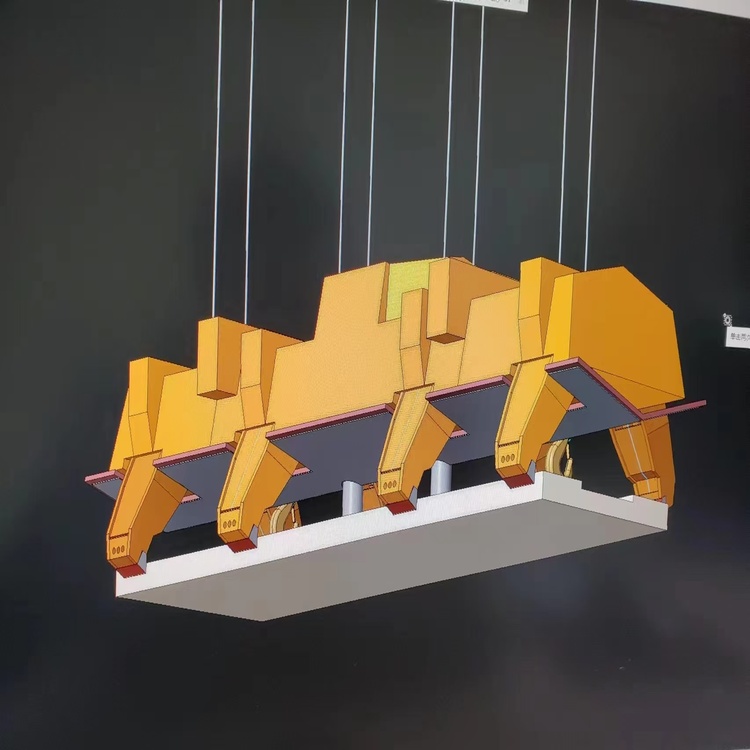

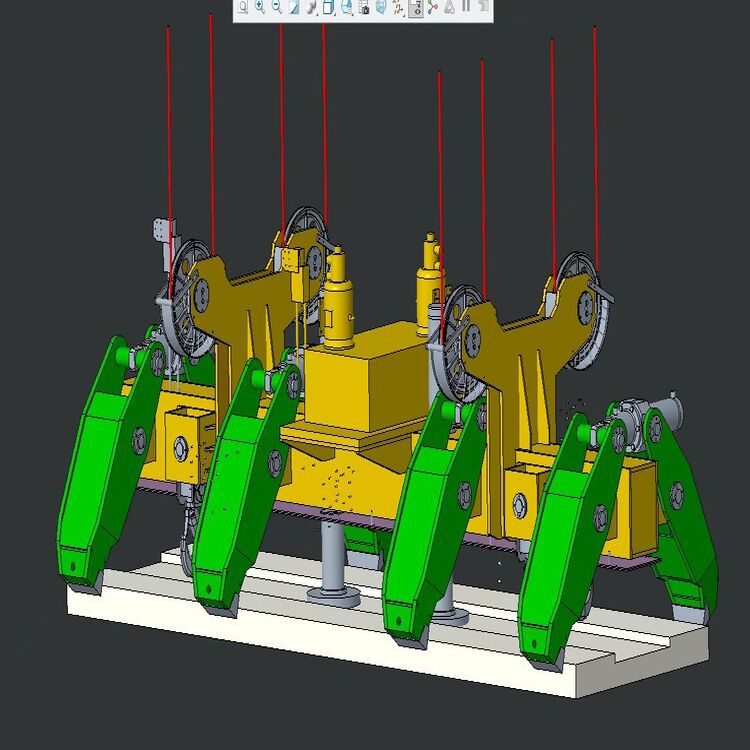

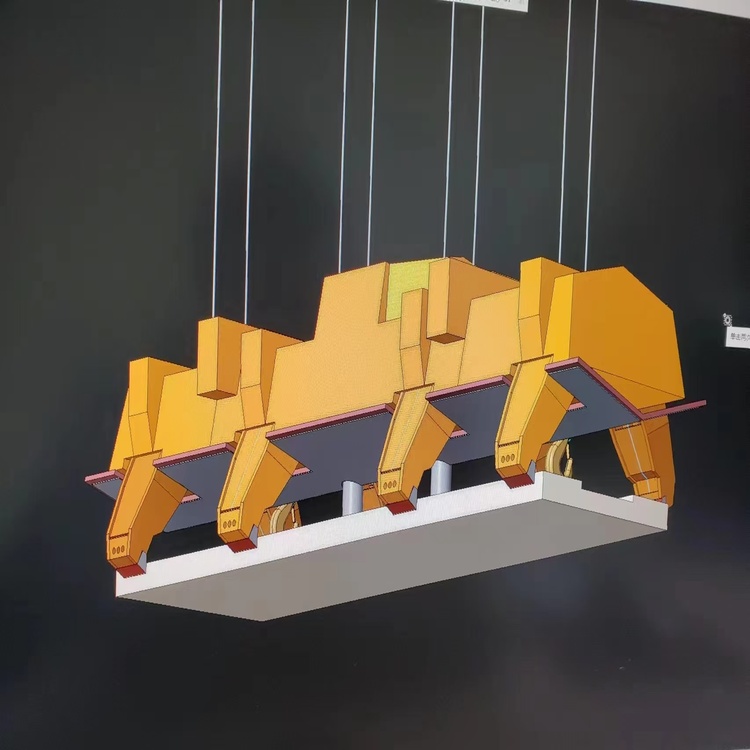

High-strength alloy steel slab clamps are essential tools in the construction, metallurgy, and port industries. How can they achieve a lifting capacity of 8 - 550 tons? Let's delve into the core technologies and compare the driving methods.

The design based on the lever principle allows a single operator to handle heavy plates, significantly reducing the manpower burden. With the use of high-strength alloy steel, these clamps have a compact structure and strong anti-fatigue performance, making them suitable for complex working conditions. The stable clamping force mechanism prevents the steel plates from slipping, avoiding production interruptions.

Here is a detailed comparison of different driving methods:

| Driving Method | Advantages | Disadvantages | Suitable Scenarios |

|---|---|---|---|

| Mechanical Drive | Low cost | Relies on manual labor, limited to light-load scenarios | Light-load scenarios |

| Electric Drive | High degree of automation | Higher cost | Continuous operation environments |

| Pneumatic Drive | Fast response, clean and pollution-free | Requires compressed air source | Explosion-proof areas |

| Hydraulic Drive | Large torque, precise control | Higher maintenance requirements | Heavy-load operations |

In the transportation of precast concrete components, these clamps can reduce the breakage rate and improve construction efficiency. In a steel plant, the use of these clamps has increased the efficiency of plate transfer, saving 3 person - shifts per day. At ports, they can adapt to bad weather and high - frequency operations.

The built - in limit and safety switches have a dual redundant design, preventing accidents. With a one - year warranty and a 48 - hour response mechanism, customers can have peace of mind.

Your plate handling problems have been solved by our technology. Our high - strength alloy steel slab clamps are not just tools but efficiency partners. They can help you build an efficient, safe, and sustainable material handling solution.

To better understand your needs and preferences, we would like to invite you to fill out a short questionnaire at the end of this article. And if you are interested in our high - strength alloy steel slab clamps, click here to learn more and get in touch with us!