In the context of Industry 4.0, the digital management of industrial fixtures has emerged as a crucial factor in enhancing production efficiency, quality, and safety. The trend towards smart manufacturing is driving companies to adopt advanced technologies for fixture management. According to industry experts, companies that implement digital fixture management can achieve a 20 - 30% increase in production efficiency and a significant reduction in maintenance costs.

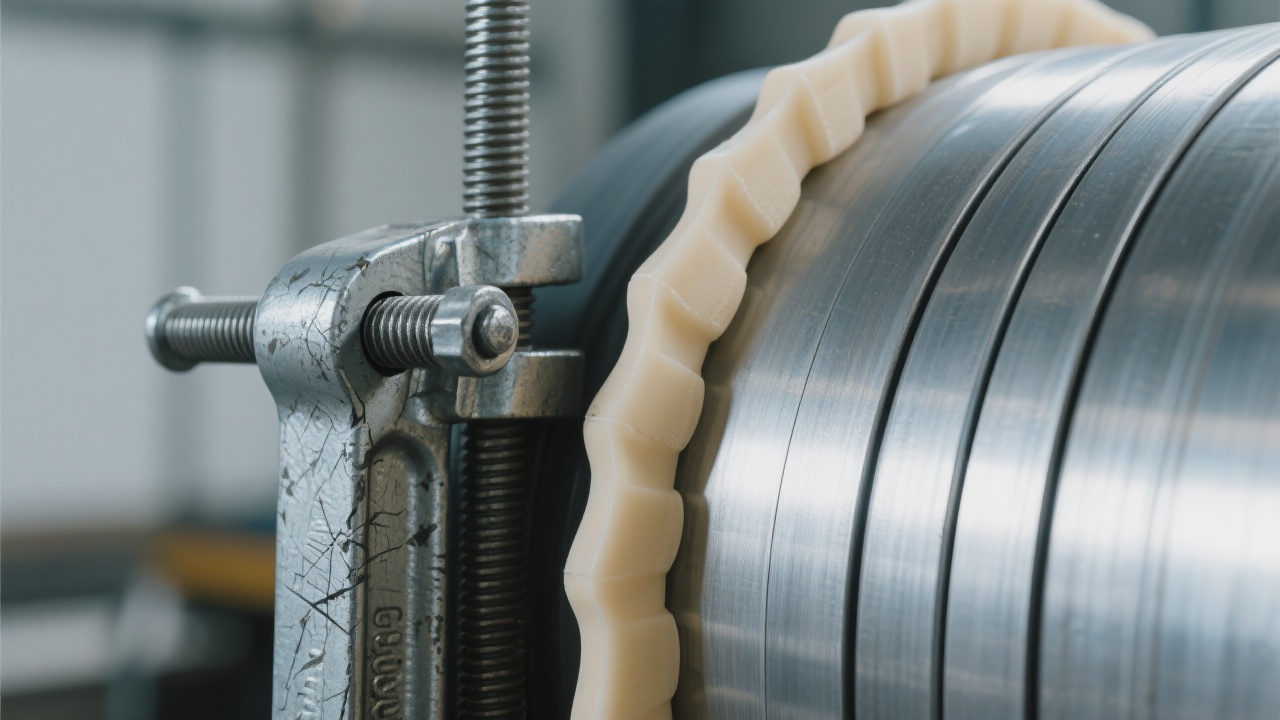

Power - type slab clamps, in particular, have unique advantages in extreme hot - rolling conditions in the steel industry. They can handle high - temperature slab materials stably, with a temperature resistance of up to 1200°C, ensuring continuous and efficient production.

The Teamcenter PDM platform plays a pivotal role in the digital management of fixtures. It enables a closed - loop management system that tracks fixture data throughout its entire lifecycle, from design and manufacturing to usage and maintenance.

During the design phase, engineers can input all the design parameters into the platform, such as material properties, geometric dimensions, and load - bearing capacities. In the manufacturing process, the platform records real - time data on production progress, quality control results, and any deviations from the design. When the fixture is in use, its operating data, including working time, load conditions, and temperature changes, are continuously monitored and stored. In the maintenance stage, the platform keeps a detailed record of all maintenance activities, such as repair history, replacement parts, and maintenance schedules.

MSC NASTRAN simulation analysis is a powerful tool for validating the structural strength and thermal deformation performance of power - type slab clamps. By simulating extreme hot - rolling conditions, engineers can accurately predict the clamp's response to high temperatures and heavy loads.

For example, in a simulation of a slab clamp operating at 1000°C, the analysis can show how the clamp's structure deforms and whether it can maintain its clamping force. Through multiple rounds of simulation and optimization, the clamp's design can be refined to ensure its reliability. Industry research shows that using simulation analysis can reduce the failure rate of fixtures by up to 40%.

A steel manufacturing company implemented digital fixture management using the Teamcenter PDM platform and MSC NASTRAN simulation analysis. Before the implementation, the company faced issues such as high rejection rates due to fixture - related problems and long maintenance downtime.

After adopting digital management, the rejection rate was reduced from 8% to 2%, and the maintenance downtime was cut in half. The company was able to proactively schedule maintenance based on the real - time data from the PDM platform, ensuring the continuous and stable operation of production lines.

The future of smart manufacturing will see further integration of technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics into fixture management. Fixtures will become more intelligent, capable of self - diagnosis and self - adjustment.

Digital fixture management will also become more widespread, enabling companies to achieve greater flexibility and competitiveness in the global market. As the industry evolves, companies that embrace digital fixture management early will gain a significant advantage.

Are you interested in learning more about how to achieve digital fixture management for your company? Click here to explore our solutions and let us help you take the first step towards smart manufacturing.